Varnish printing can really change how your custom packaging looks.

When you want your packaging or printed boxes to catch customers’ eye, think about using varnish to give your colors more dimension or to add a gentle touch that shows off your brand.

What is Varnish In Printing?

Varnish is a protective and decorative transparent coating that adds a beautiful, clear gloss to printed materials. It helps to preserve the quality of the print and gives it a professional and attractive appearance. Whether applied during or after printing, varnish adds an extra layer of protection against fingerprints, smudges, and scuffs, ensuring that your printed materials look their best for longer. It also helps to enhance the vibrant colors and overall style of your packaging, making it stand out on the shelf.

4 Common Types of Varnish In Tin Packaging

When it comes to choosing the right varnish for your tin packaging, it’s important to understand the different types of varnish available in the market.

Each type of varnish has its unique effect that can affect the look and feel of your packaging, as well as its level of protection.

Here are most varnishes used in tin packaging:

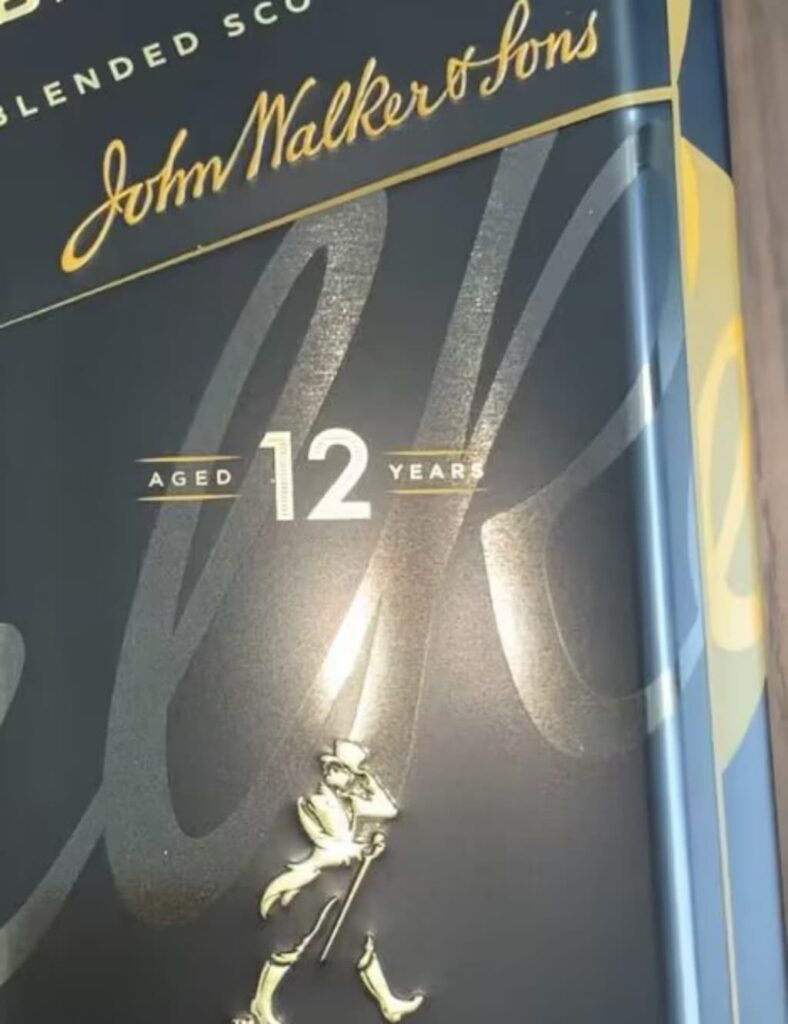

Gloss Varnish

Gloss varnish is the most popular choice for tin packaging because it creates a high-gloss finish that enhances the overall aesthetic of the packaging.

The glossy finish can make colors appear more vibrant and can give tin packaging a luxurious, premium feel.

Gloss varnish can be used for various packaging, such as food, beverage packaging, cosmetic packaging, and luxury packaging.

Matt Varnish

Matt varnish gives a softer, more subtle appearance and is non-reflective, making it better suited for packaging with a lot of text or text that needs to be read from a distance. However, it does not stand out as much as gloss varnish.

One of the benefits of using matte varnish is that it can be used to create contrast and depth in packaging designs.

It works well when combined with other finishes, such as gloss or spot varnish, to create visual interest and highlight specific design elements.

Spot Varnish

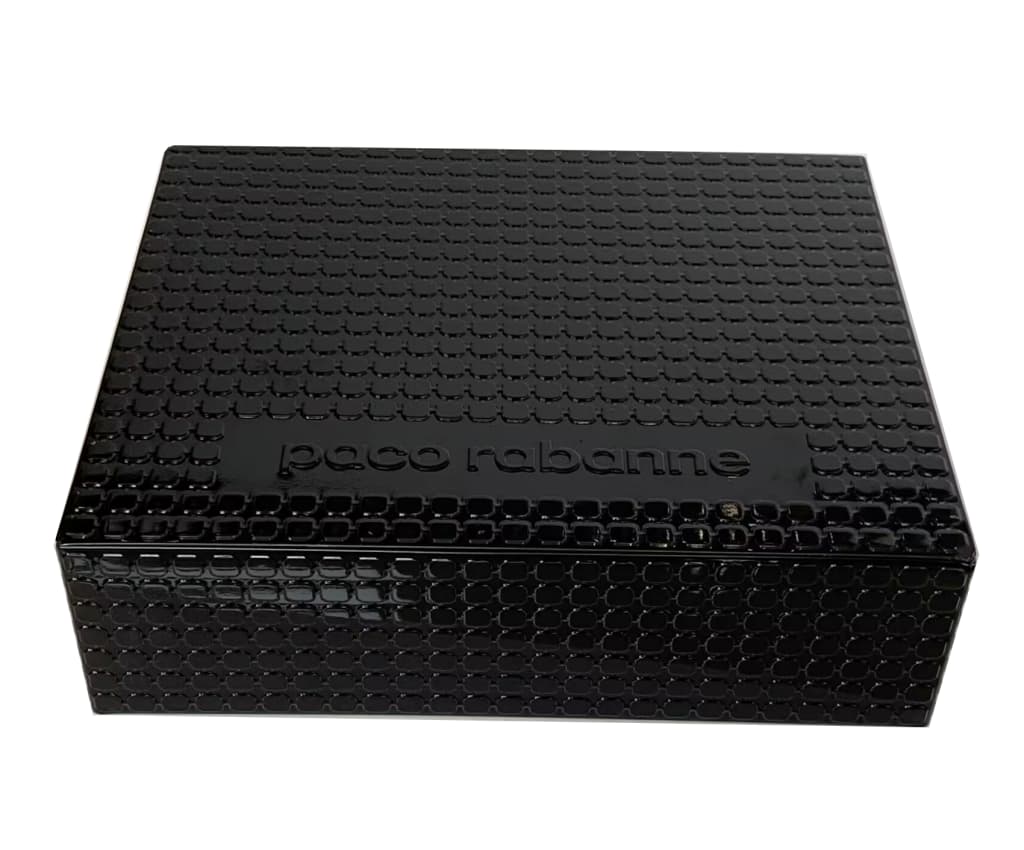

This technique combines matte and gloss varnish to create a really 3D effect. The matte varnish is applied to all areas except where a glossy effect is needed, allowing the glossy areas to shine while giving the rest of the packaging a softer look.

Spot varnish is often used for high-end cosmetics, fragrances, wine packaging, and fashion products, where luxury brands want to create a sense of exclusivity and sophistication.

Crackle Varnish

Crackle varnish, also known as crackle finish or crackle glaze, is a type of decorative finish applied to various surfaces, including tin packaging, to create a unique aged or distressed appearance. This finish results in a cracked or cracked-look pattern on the surface, resembling aged paint or weathered materials. It’s often used to achieve a vintage, antique, or rustic aesthetic.

The Advantages of Varnish In Tin Packaging

Varnish is a clear coating that is often applied to tin packaging to protect the surface and enhance the appearance of the product. There are several advantages to using varnish in tin packaging:

- Customizable: Varnish can be customized to achieve a variety of finishes, including gloss, matte, and satin, as well as different levels of sheen.

- Improved protection: Varnish provides an extra layer of protection for the tin packaging, helping to prevent scuffs, fingerprints, and smudges from damaging the surface. This can be particularly useful for products that will be handled frequently or shipped long distances.

- Enhanced appearance: Varnish can be used to add a glossy or matte finish to the tin packaging, which can improve the overall aesthetic of the product. It can also be used to make a particular image or typography more prominent, enhancing the visual appeal of the packaging.

- Increased perceived value: By adding a high-quality finish to the tin packaging, varnish can increase the perceived value of the product. This can be particularly useful for companies that are competing in a crowded market and want to differentiate their products from those of their competitors.

- Improved print quality: Varnish can help to preserve the quality of printed images on tin packaging by protecting them from fading or smudging. This can be particularly important for products that will be displayed for an extended period of time.

The Disadvantages of Varnish In Tin Packaging

While varnish can be a useful tool for enhancing the appearance and protecting printed materials, it may not offer the same level of protection as other types of coatings, such as aqueous coating and UV coating.

Additionally, varnish can be susceptible to yellowing over time, which may affect the appearance of the finished product. It is important to be mindful of the environmental impact of varnish, as it may require careful application in order to prevent the release of toxic compounds into the atmosphere unless aqueous-based varnishes are used. It is worth considering these potential limitations when deciding whether to use varnish in your printing projects.

Make Good Tin Packaging with Varnish For Your Branding

If you are considering using varnish to enhance the appearance of your tin packaging, the expert printers, packaging specialists, and artists at Tinshine can help.

Our tin factory has the knowledge and experience to guide you through the process and help you choose the best options for your tin packaging. Even if you are not sure exactly how you want your packaging to look, the team at Tinshine can draw from a variety of styles and inspirations to create a look that you will love. Varnish is just one of the many techniques that our factory can use to add a touch of elegance, beauty, style, and much more to your packaging to make it more attractive and impactful.

To learn more about the wide variety of options available at Tinshine, don’t hesitate to give us a call or email us. We will be happy to listen to your needs and formulate a plan of action to help you take the next steps with confidence.