Metal packaging holds a significant position among the four major packaging materials (paper, metal, glass, plastic), and its importance continues to grow in our society. With its exquisite printing, durability, easy opening, and superior sealing performance compared to paper and plastic packaging, metal packaging plays a crucial and irreplaceable role in the food and beverage industry.

According to the statistics from the World Packaging Industry Association, metal packaging currently ranks third in terms of usage among packaging materials in China, Japan, and Europe, trailing behind paper and plastic packaging. In the United States, metal packaging has overtaken plastic to claim the second position, while paper packaging still maintains its top spot in the packaging industry.

Two Key Factors Driving the Significant Increase in Metal Packaging Usage

China’s Ban on plastic waste imports Suppresses Plastic Packaging Usage

China has long been the world’s leading plastic waste importer. However, in January 2018 the Chinese Government enacted a new policy to permanently ban the import of most plastic waste into the country.

According to official data from the United States, in 2016 alone, over 1.4 million tons of plastic waste and 13.2 million tons of paper waste were exported to China. With China’s refusal to accept “foreign garbage,” countries in Europe and America have had to reconsider their waste export practices. This has led to a more cautious approach to using plastic packaging

Metal Packaging is Infinitely Recyclable

Paper packaging heavily relies on resources from forests, causing significant damage to natural ecosystems through overuse. On the other hand, metal materials are abundant and capable of infinite recycling. As a result, metal packaging holds great promise for the future, with its usage expected to increase steadily.

According to the International Metal Packaging Association’s statistics and projections, global demand for metal cans reached 3.644 billion units in 2014, with a trade value of $44.86 billion. It is estimated to rise to 4.3 billion units with a trade value of $52.83 billion by 2020, showing a growth rate of 2.9%.

Over the past decade (2006-2015), metal can usage increased by an impressive 106%, and it is projected to reach $13 billion by 2020, accounting for a quarter of the global total.

Types of Metal Cans

Currently, there is no official standard or precise classification method for metal cans. However, we can still categorize them based on their purpose and manufacturing processes. The comprehensive classification includes:

- Beverage cans

- Food cans

- Aerosol cans

- Coffee cans

- milk powder cans

- steel drums

- Tin boxes

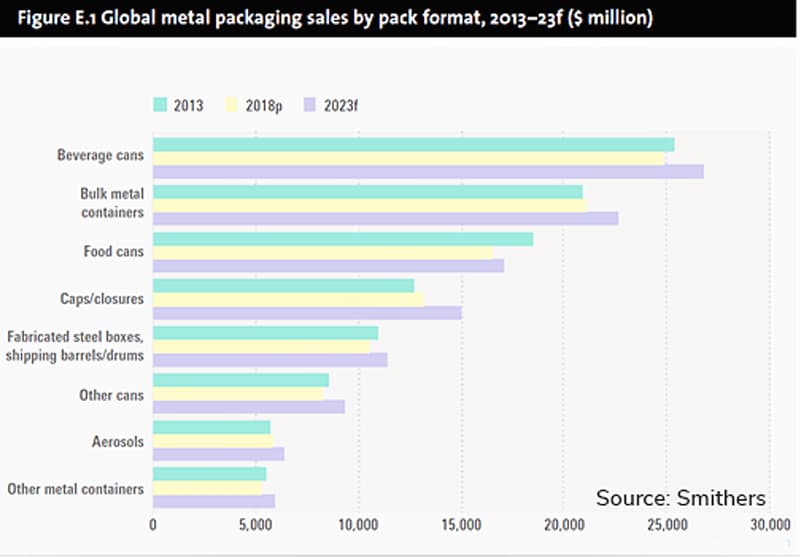

According to The Future of Metal Packaging and Coatings in 2023, the global metal packaging and coatings market was almost $105.5 billion in 2018. Total value is forecast to increase at 1.6% year-on-year to 2023, pushing overall value to $114.4 billion.

A significant portion of this market value comes from beverage cans, currently the most popular type of metal packaging. Beverage cans hold a large share of nearly 45% of the market. Another important segment in the metal packaging industry is food cans. Food cans are widely used for packaging various food products and play an important role in preserving and protecting the contents.

Four Major Advantages in Metal Packaging

Metal packaging provides numerous benefits to attract consumers and give brands a competitive edge. A multitude of tin sizes, shapes, and printing designs can be manufactured to meet a wide range of market needs.

Lightweight

Lightweighting has been a leading trend within the metal packaging industry over the past decade, in sectors ranging from food and beverage cans to aerosols. This enables packaging manufacturers and brand owners to reduce their environmental footprint and therefore improve their sustainability credentials, while also reducing costs.

The use of advanced materials like DR steel and JATT (developed by JFE Steel) has provided a solid foundation for reducing weight and diversifying can designs. DR steel offers excellent strength while reducing material thickness, ensuring the can’s axial and radial strength is not compromised. However, it poses challenges in processing, making techniques like flanging, scoring, stretching, and necking more difficult.

On the other hand, JATT material improves metal processing performance by adjusting the metal’s molecular structure. Through secondary cold rolling, it achieves the same strength as DR material, offering better solutions for can processing and customization.

Innovation

For almost 200 years, the shape of food and drink cans stayed the same, and this made shoppers feel a bit tired of seeing the same thing for so long. But now, because the way we make cans has improved a lot, we can make them look and work in new and exciting ways. This is all thanks to cool techniques like making cans bigger, shaping them differently, and stamping designs onto the metal.

We can now use special printing tricks to make metal packaging stand out. Imagine using lasers to print designs, making the surface look cracked on purpose, or using ink that changes color with temperature. These options give us more ways to make metal packages look different and cool.

Digital Transformation

Following the footsteps of paper packaging, the “one can, one code” trend has become prevalent in metal packaging. Using inkjet printing, unique and variable QR codes are added to each package, making them distinct. QR codes give a new life to packaging, offering both uniqueness and diversity. Each tin can be scanned to trace manufacturing, prevent counterfeiting, and combat diversion.

Scanning also allows customers to earn loyalty points and rewards. Additionally, metal packaging can use QR codes to connect to the Internet, providing richer content like websites, ads, and others.

Considering that inkjet QR codes are susceptible to damage or tampering, tin manufacturers collaborated with research institutions to introduce the “Micro QR Code” technology. Using patented algorithms, encryption, and high-definition overprinting, the QR code size was reduced to 40µm.

These “Micro QR Codes” can be arranged to form a visible QR code, even when a significant portion is damaged. Additionally, to preserve the printing patterns, “Micro QR Codes” can be invisibly printed in specific areas of the packaging, which can be read using specialized scanning devices. This significantly enhances the effectiveness of anti-diversion measures.

Switch away from BPA

People are becoming more concerned about the use of BPA in metal packaging. BPA is a chemical that’s been used in the past to line the insides of cans to keep the food fresh. However, there have been concerns about its potential effects on human health.

To switch away from BPA, companies are using alternative materials to line the inside of the cans. These alternatives are safe and don’t have the same potential health risks as BPA. This change is especially important for products that are meant for babies, like infant formula, as well as for foods that are acidic, like tomatoes, which can make the BPA leach into the food.

The switch to BPA-free linings in metal packaging means that people can enjoy their food without worrying about harmful chemicals. It’s a way to make sure that the packaging is as safe as the products inside.

FAQ:

Yes, metal packaging is easy to sort and recycle due to its magnetic properties.

Certainly! Metal packaging can be decorated, printed, and embossed using a variety of colors and effects, allowing for a premium image and increased brand visibility.